Repairing the Whirlpool and KitchenAid Ice Machines

Inevitable Problems and How To Fix Them

Do It Yourself

OR

Know What Your Service Technician Should Be Doing

Where to Find Parts and How Much They Should Cost

Detailed Instructions Below on Troubleshooting, Diagnosis, and Repair

Written by a fan and aficionado of these machines.

My most recent update to this page was July, 2025.

The do-it-yourself parts and mail-in services I offer below are currently available;

I am still actively engaged in this business.

The under-counter Whirlpool ice machine is a stand-alone $2000 appliance which makes gourmet

clear ice such as for a wet bar.

It has been labeled and sold as KitchenAid, GE (General Electric), Sub Zero, Scotsman, Viking, Estate, GM/Frigidaire, Maytag, Amana, Roper, Inglis, Ross Temp, Marvel, and Sears Kenmore brands, and is similar

in quality and specifications to the under-counter Jenn-Air 50 lb/day ice machines currently sold.

This luxury ice machine should not be confused with the ordinary ice maker that is part of

a refrigerator-freezer; the former magnificent engine makes crystal-clear, flavor-free, ice cubes.

A refrigerator-freezer ice maker produces cloudy ice in a stale-garlic flavor, typically in odd crescent shapes,

and stuck together.

The ice machine's product is clear, pure, flavorless ice cubes which are luxuriously wet and loose, like a handful

of flawless diamonds scooped from a mountain spring.

Owning this machine once in your life will spoil you, like many of my correspondents who say they will never

again return to refrigerator ice. Among life's material joys and comforts, the little cubelets are both innocent and enduring.

The under-counter Whirlpool ice machine is a stand-alone $2000 appliance which makes gourmet

clear ice such as for a wet bar.

It has been labeled and sold as KitchenAid, GE (General Electric), Sub Zero, Scotsman, Viking, Estate, GM/Frigidaire, Maytag, Amana, Roper, Inglis, Ross Temp, Marvel, and Sears Kenmore brands, and is similar

in quality and specifications to the under-counter Jenn-Air 50 lb/day ice machines currently sold.

This luxury ice machine should not be confused with the ordinary ice maker that is part of

a refrigerator-freezer; the former magnificent engine makes crystal-clear, flavor-free, ice cubes.

A refrigerator-freezer ice maker produces cloudy ice in a stale-garlic flavor, typically in odd crescent shapes,

and stuck together.

The ice machine's product is clear, pure, flavorless ice cubes which are luxuriously wet and loose, like a handful

of flawless diamonds scooped from a mountain spring.

Owning this machine once in your life will spoil you, like many of my correspondents who say they will never

again return to refrigerator ice. Among life's material joys and comforts, the little cubelets are both innocent and enduring.

Besides this delicious indulgence, the ice machine also makes an excellent source for controlled cold-plate chilling necessary to the

operation of an even greater luxury, the home soda fountain (see my page on home carbonation).

On this page, however, we are only concerned with the ice and how to keep the machine running.

This residential ice machine creates 8 x 7 x 1/2 inch slabs of ice by recirculating

water over a metal evaporator plate chilled by an R-134a chiller (or R-12 before

the early 1990s; this basic machine design goes back to the 1950s). When a slab of ice reaches the finished thickness, a thermostat

triggers the harvest cycle, which reverses the chiller to warm the evaporator plate,

until the ice slab slides onto a cutter grid. The cutter grid consists of nickel-chromium ("Nichrome" is

one brand) resistance wire which is warmed by a low-voltage electric current.

The ice slab rests on the heated wires, and the wires slice through the slab, first in one direction on the

top layer of wires, then the perpendicular direction on the lower layer, yielding cubes of ice which drop

into an insulated ice supply bin.

The original machines were produced in an 18-inch width for a standard 34.5-inch under-counter height.

Since 1999 a 15-inch version is also available.

The only part of this machine which chills is the evaporator plate at the top of the machine where the ice forms.

Unlike a conventional refrigerator-freezer, the ice storage bin is only insulated.

The air inside is not refrigerated, and the temperature never drops below freezing.

This bin is more or less like a portable ice chest but built into the cabinet.

This is an essential principle of a wet ice machine.

The cubes stay loose and are always slowly melting, so the machine runs to make new ice to keep the bin filled and

to make up the ice you withdraw for use.

|

I got to know these machines quite well over the last 24 years.

In 1995 I moved into a home equipped with one, and learned about this unusual appliance by doing my own repairs.

It eventually became an essential part of my home carbonation and soda fountain efforts (see link above).

I got to know these machines quite well over the last 24 years.

In 1995 I moved into a home equipped with one, and learned about this unusual appliance by doing my own repairs.

It eventually became an essential part of my home carbonation and soda fountain efforts (see link above).

Then in 2002, I wound up owning a truckload of them, after

I went to the bankruptcy auction of the infamous Enron accounting firm,

Arthur Andersen, where I had expected

to buy various assets for my computer business.

Their corporate skyscraper suites were furnished with a large quantity of these machines, recently purchased.

While I wanted to buy one to have as a spare, the auctioneer abruptly insisted on selling all of them as one lot.

Of course, nobody else at a business-equipment auction wanted such a haul, but I saw an opportunity, knew what I was dealing with,

and took them all for 5 cents on the dollar.

I made a handsome profit reselling them one-at-a-time on eBay (sorry, they're all gone now), but in the process I

had to become expert at diagnosing and repairing them, using my background as an engineer by profession.

This field experience provided a conclusive demonstration of what were the most common repair problems,

which led me to create this Web page for the benefit of fellow ice machine owners.

Having maintained this Web page for some years, I have corresponded personally with thousands of other ice machine owners, and

performed (or at least consulted on) all of the repair problems presented by these machines.

Below you will find the accumulated wisdom for diagnosis and repair procedures, obtaining original parts,

improvising ersatz parts, and dealing with hired service technicians.

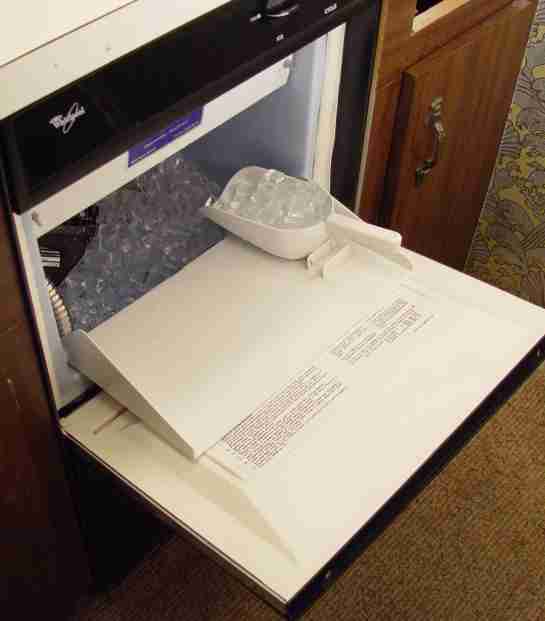

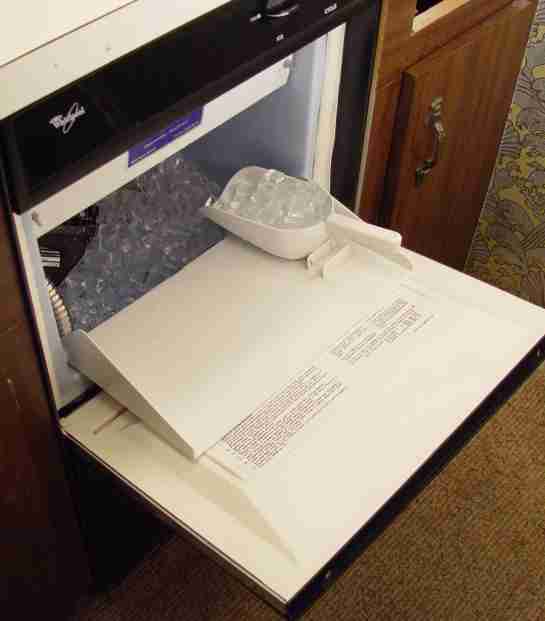

The photos here show my personal unit made in 1997, model EC5100XFB0.

The essentially identical machine has been sold for years and years under a variety of brands,

model numbers, and styles of decor.

Other than a change away from R-12 refrigerant to R-134a about 1992, and a change from electromechanical

controls to computerized electronics about 2002, the principles, components, and physical arrangement have

been the same for many decades.

An excellent source of information, including parts diagrams, parts catalog,

and pricing is available at partselect.com

and at sears.com, even if they're not the best place to buy parts.

You can enter your specific model number there and compare the parts involved in your repair

to those specified for mine.

Similar models include:

ACS50

ACS501

ACS502

CCS51AEL

CECS2AE1

CHCS51AE1

CSWE1 CSW1AE CSW1AE1B5 CSW45 CSW45PA1B0 (Scotsman)

EC5100

EC5100XEB0

EC5100XEB1

EC5100XEN0

EC5100XEN1

EC5100XEW0

EC5100XEW1

EC5100XFB0

EC5100XFB1

EC5100XFN0

EC5100XFN1

EC5100XFW0

EC5100XFW1

EC5100XL

EC5100XP

EC5100XT

EC5100XT1

EC510BXD0

EC510NXD0

EC510WXD0

EC510WXE0

ECB5100XFB

EHC511

EUC050A1

ZDI15

ZDI15CBB

GI1500PHB0

GI1500PHB3

GI1500PHB6

GI1500PHW0

GI1500PHW3

GI1500XH

GI1500XHB0

GI1500XHB1

GI1500XHB2

GI1500XHB3

GI1500XHN0

GI1500XHN1

GI1500XHN2

GI1500XHN3

GI1500XHS0

GI1500XHS1

GI1500XHS2

GI1500XHS3

GI1500XHT1

GI1500XHT2

GI1500XHT3

GI1500XHW0

GI1500XHW1

GI1500XHW2

GI1500XHW3

GI1500XHW7

GI15NDXTB

GI15NDXTS

GI15NDXXS

GI15NFLTS0

GI15NFRTB0

GI15NFRTB1

GI15NFRTB2

GI15NFRTB3

GI15NFRTB4

IACS501

IACS50E1

IM30

JEAC501

JEAC50SL0

JEAC50SL1

JEACS50SL0

JEACS50SL1

JLAIC5053

JT051CAE1612

JT051CAE2511

JT051CAE2512

JVGC535A0

JVGC535A1

JVGC535W2

KUIA15NLH

KUIA15NRH

KUIA15NRHS9

KUIA15PLL

KUIA15PRL

KUIA15RRL

KUIA18NNJ

KUIA18NNJS5

KUIA18PNL

KUIA18PNLS1

KUIC15

KUIC15NRTS0

KUIC18

KUIS155H

KUIS155HLS3

KUIS155HRS3

KUIS15NNZW0

KUIS15NNZB0

KUIS15NRH

KUIS15PRH

KUIS185FBS0

KUIS185J

KUIS185JSS0

KUIS185JWH2

KUIS18NNJ

KUIS18NNJW5

KUIS18NNTW1

KUIS18PNJ

KUIV18NNM

MA15CL

MIM1555ZRS0

ML15CL

ML15CLG

ML15CP

ML15CPG

O53CAE1610

O53CAE1612

RC-50-SC (Ross Temp)

VUIM153DRSS (Viking Range Corporation)

ZD115CBBE

ZDIC150EBB

ZDIS150

ZDIS150WBB

ZDIS150WSS

ZDIS150WWW

ZDIS15CSS (GE Monogram)

198.887482

106.86482690

106.86482691

198.8814831

3KUIS185V0

235S0

501-ISC (SubZero)

JIM1550ARW

JIM158XBRS

JIM158XBRSO (Jenn-Air)

My trusty unit shown at left is still running after all these years.

I have had to: repair the grid several times, replace the harvest thermostat

with an electronic timer, replace the water solenoid valve, and recharge the unit

with refrigerant. The basic refrigeration mechanism is very sturdy and reliable.

Other owners of these machines have 30-year-old specimens still running.

|

Before you go off ordering expensive parts, or rashly discarding a failed unit,

see if my information below can't help you diagnose and repair the trouble more economically.

Let's first discuss the three most common problems that likely brought you here in the first place.

After that, we'll detail the universe of rarer problems.

As wonderful as this machine performs,

there are three chronic problems with Whirlpool's otherwise excellent design

resulting in very costly repair calls, typically after only a few years of constant operation:

- The rather thin wire in the cutter grid

breaks.

The result is that the slabs of ice back up in the machine and no ice cubes are cut to fall into the supply bin.

- On pre-2002 machines with electromechanical controls, the solder joint bonding the harvest thermostat to the evaporator plate cracks and breaks loose,

due to repeated infiltration and expansion of water in the freeze-thaw cycles.

The thermostat no longer senses the actual temperature of the evaporator plate, and takes longer to trigger

a harvest cycle.

The repeated cycles of icing slowly push the bracket holding the capillary tube farther and farther away

from the evaporator plate.

The intervals of harvesting become longer and longer, despite the manual adjustment to the

thickness setting that should make the cycles shorter.

Eventually the machine will not trigger a harvest cycle at all, and one thick slab of ice sits on the evaporator

plate, never to be harvested, and no ice is produced in the supply bin.

- The solenoid valve that controls water flow to the reservoir fails in one of two ways.

One, it may fail to close completely, resulting in a continuous trickle of warm water into the reservoir, which

at first slows ice production, and eventually stops ice production altogether if it gets bad enough.

Two, it may fail to open fully or at all, so that the reservoir never fills, and only thin ice slabs, or no ice at all,

is produced.

Not only do these problems suggest a house call from an appliance service, but these service calls can

be very expensive. Ice machines are relatively rare items, and the expertise to diagnose and repair them

tends to command a premium price, as do the manufacturer's sole-source parts.

More typically, you're likely to get someone who may know how to fix a common refrigerator, but

doesn't understand ice machines well enough to diagnose their unique types of problems.

If you're like me, you may find that you can perform a costly repair yourself, at minimal expense.

What you need is some information and diagnostic analysis, which is why I wrote this Web page.

Some repairs I'll describe may be beyond your abilities, but even if you're not a do-it-yourself'er,

you can use this information to make a firm diagnosis yourself.

At the very least, you will be able to critique whether a service technician is giving you a correct diagnosis and

a fair price for repairs. In the grim case where your machine is not worth fixing,

you can decide this without having to pay for a service call.

I have published this information as part of my machine shop pages,

because these repairs have to do with metal itself (nickel-chromium wire, solder), or with parts

or suppliers closely associated with metalworking, even though there is

no actual machining involved.

Understanding the Unit via Service Manuals

Before you attempt to diagnose or repair a problem, you may wish to study some of the service manuals I've been

able to collect over the years. Different manuals cover the various designs and models from the 1970s to the present, so

pick the manual(s) with the closest match to the type of machine you have.

If you're not sure what is the closest, the KitchenAid KAR manuals are the best technical reference manuals, as they

cover all technical details and diagnostic procedures for the basic Whirlpool machine, which what all the brands

(Whirlpool, KitchenAid, GE Monogram, Jenn-Air, Maytag, etc.) are actually built from.

- The Service and Wiring Sheet 2180831 (46KB PDF file) describes

later versions of the older electromechanical-controls machine (EC5100 series, manufactured up until about 1999 and

sold by appliance dealers for a few years thereafter).

The Tech Sheet 758860-E and 758846-C (167KB PDF file) describes the earliest models.

The earliest models used the spring-clip type cutter grid described below, and described in the

Whirlpool repair parts list for EC5100XP models.

- The later version of the machine, introduced in 1999, uses an electronic printed circuit board instead of electromechanical controls;

this was a fundamental change in the design which must be considered in diagnosis and troubleshooting.

Nearly all working machines today are of this electronic design.

Working electromechanical machines are becoming rare as they age

into necessary repairs, typically demanding orphaned parts like thermostats that are hard to find.

The recent version of the electronically-controlled Whirlpool (and KitchenAid branded) machine (2007 and after) is described by

Service and Wiring Sheet 2324311C.

The very first version of electronic control models (starting 1999)

were described by the Service and Wiring Sheet 2217233-REL and 2217235-REL (224KB PDF file).

A later version (2005) which seems to have the same information is Service and Wiring Sheet 2313728-REL.

- The GE Monogram series (ZDIS150) has a similar Technical Data sheet 162D9144P005 (part numbers 2217278 or 31-51316-1),

and the Technical Service Guide (part number 31-9196, March 2010) for all ZDIS150 models (including ZDIS150WSS, ZDIS150WBB, ZDIS150WWW; these

three-letter suffixes on the ZDIS150 model code just indicate the color decor of white, black, or stainless).

This GE branded machine appears to actually have been made by Whirlpool.

These manuals are well-written but not as thorough as KitchenAid's KAR manuals, so it may be necessary to study them both to get a full understanding.

- If you have the newer electronic controls,

read these key sections of the service manual for the Whirlpool GI1500 series ice machine (384KB PDF file, 34 pages), which

includes wiring diagrams. The theory of operation and troubleshooting information is worth reading to understand older models as well.

Also see the parts diagrams.

The manuals cover the KitchenAid brand versions of the Whirlpool machine.

Here also is the owner's manual use and care guide.

The KitchenAid models are designated KUIS155 and KUIS185 with suffixes for variations in finish style.

- Various versions of the electronic control board (part numbers 2185947, 6100499, 2304016) have slightly different timing in the run sequence chart [1-page PDF file].

- Whirlpool Instruction Sheet 4388700 Rev A 6/04 (view that document [2-page PDF file])

which details an update to the

electronic controls released in 2004. The older PC board was Whirlpool part number 2185947.

Updated boards are Whirlpool part numbers 6100499 and the most recent 2304016.

The update improves the cycle timing and diagnostic sequence,

and provides flashing LED trouble codes when the controller detect faults in the machine.

The latest version, Whirlpool 2304016, differs from Whirlpool 6100499 in adding numerous intelligent features:

a delay of 30 seconds at initial power-up

before starting the compressor, a minimum/maximum freezing time of 15 to 25 minutes, 1 minute maximum water refill time,

forced 25-minute freeze with 4-minute harvest timed cycle time if you disconnect the evaporator thermistor,

forced shutdown with half-second flashing LED if thermistor-controlled harvest time exceeds 16 minutes,

forced shutdown with one-second flashing LED if the bin thermistor fails,

and diagnostic flash codes for thermistor tests are generated when running the cleaning cycle (see the manual for details).

So the detected faults in these later models include a too-long harvest cycle, and a failed bin or evaporator thermistor.

- See also my detailed parts diagrams and catalog for the older

electromechanical machines, and compare them to your unit.

- KitchenAid KAR-19 technical education job aid 4317408 document [5 MB PDF file, 74 pages],

for the "2007 Design" version of the KitchenAid branded machines manufactured by Whirlpool.

This is a training manual for service

technicians working on ice machines. Much of it just repeats what is in the service manual specific to a given model,

but there are detailed procedures for replacing all the components in the general machine.

An older version of this manual for design years from 1999 to 2007

is the KitchenAid KAR-14 technical education job aid 4317339 document [large 60 MB PDF file, 80 pages].

Find the design year of your KitchenAid model by the ninth letter in the model number:

H=1999, J=2000, K=2001, L=2002, M=2003, S=2006, T=2007 (etc).

Find the year of production in the second letter in the serial number: M=2002, P=2003, R=2004, T=2006, U=2007 (etc);

the third and fourth digits indicate the week of production.

The corresponding Whirlpool model numbers for the 2007 design update seem to be the GI15NFRTB pattern.

(The chief feature introduced newly into the 2007 design was a drain pump with water level sensor in the reservoir; this allows

the control board to exert powered control over both filling and draining of the reservoir, thus improving the reservoir water freshness,

reducing the amount of water required to refill, and detecting mechanical problems with filling and draining.

The fill valve also meters the incoming water flow rate, containing its own complicated electronic circuit board to do so.

Harvesting apparently triggers not just from evaporator thermistor temperature, but also from low water in the reservoir.

While this newer gadgetry improves performance and efficiency, it makes for more things to possibly go wrong, complicates diagnosis and repair,

and requires expensive manufacturer-specific parts to replace anything that fails.)

The 2007 and later Whirlpool or KitchenAid machines come with two brief service documents tucked into the chassis: the

KitchenAid KUIC18PNTS2 Diagnostic Procedure and

the KitchenAid W10217947A Service Sheet.

Some KUIS18 units came with the Whirlpool W10206442E Service and Wiring Sheet.

- Jenn-Air JIM158XBRS models Service and Wiring Sheet.

- Marvel IM30 service data sheet [PDF file, 2 pages] and service manual [PDF file, 35 pages].

This model is not the Whirlpool type, but similar in principle,

with good instruction in the theory of operation and diagnosis in the service data and manual.

- The Embraco Compressor Application Manual

(search for download [google.com])

is an excellent reference for testing, diagnosis, and repair of the machine's refrigeration compressor.

-

The W10492485 service and wiring sheet [1.3MB PDF file, 5 pages].

This is for the Maytag MIM1555ZRS0 model, which appears to be the Whirlpool guts in a Maytag label and cabinet.

This sheet also applies to the KitchenAid KUIS15NNZW0 and KUIS15NNZB0 models.

The design contains four electronic sensors to confuse the controller (and you) when they fail:

three thermistors (evaporator, bin, unit), and a reservoir water level sensor.

- If you should come across any additional documentation for these machines, please send them to me via email for posting here.

Repairing the Ice Cutter Grid

If your cutter grid breaks, the replacement part (326566 Grid

Assembly) will cost you $224.75 from Whirlpool (2008 pricing), perhaps on top of a service

call expense if you didn't diagnose the problem yourself. Yet this is an easy problem to diagnose, and perhaps

even fully repair, yourself. The defect is repairable by replacing about 18

feet of a certain gauge and alloy of nickel-chromium wire.

New grid wire kit: I keep a bulk supply of this wire on hand, US-made, top quality.

I'll promptly send you 20 feet of the correct wire by first class mail for $26. Ships to USA and international addresses.

Orders are processed same- or next-day from receipt.

This is the same grid wire used on all makes and models from the 1970s to the present, and substitutes for

the wire in Whirlpool rebuild kits 370853, 4387020, and 2185611; and the GE Monogram kits WR29X10075, WR02X12734, and WR02X12735;

competitive prices on these kits are upwards of $80.

To order, see the detailed ordering page.

You can also order a bulk supply of 100 feet, which is sufficient for five repairs, for $80.

Newer-type grid connector kit: At left is the connector used on the newer type grids.

These connectors rarely fail, but when they do they are almost impossible to find.

The nylon shell at left is used on the grid itself,

and on the right is the shell used on the machine chassis.

The grid uses the plug shell with the receptacle pins, and the chassis uses the receptacle shell with the plug pins.

One of the crimp pins for each shell are also shown.

I stock these items as a complete replacement kit consisting of one of each shell and two of each crimp pin.

With this kit you can replace the grid connector, the mating connector on the machine, or both.

Order here.

Newer-type grid connector kit: At left is the connector used on the newer type grids.

These connectors rarely fail, but when they do they are almost impossible to find.

The nylon shell at left is used on the grid itself,

and on the right is the shell used on the machine chassis.

The grid uses the plug shell with the receptacle pins, and the chassis uses the receptacle shell with the plug pins.

One of the crimp pins for each shell are also shown.

I stock these items as a complete replacement kit consisting of one of each shell and two of each crimp pin.

With this kit you can replace the grid connector, the mating connector on the machine, or both.

Order here.

Older-type grid connector: You can also use this newer-type connector kit to replace both sides of the older black-rubber 2-prong grid connector,

since the older connector is no longer available.

This connector is what we use to refurbish older grids with a failed old connector.

Detailed how-to: See my replacement instructions for the ice machine grid connectors.

My cutter grid has two levels,

one that cuts "north-south" and a second that cuts "east-west"; each of

these is about 8 feet of wire creating a 10 ohm resistance. These two are

wired in parallel to create about a 5 ohm resistance. You can check the

resistance with an accurate volt-ohmmeter, and measure the wire diameter

with a micrometer or calipers, to make sure you have a similar design.

Email from readers of this page confirms that this grid

design and wire type is the same across all makes and models.

There are two possibilities for the spacing of the grid wires, which

correspond to "cubelet" (3/4 inch square cubes) versus "cube" (1-1/4 inch square cubes) size ice, although

I've never, ever seen anything but the 3/4 inch version.

On some models, the low-voltage transformer that powers the cutter grid also powers a bin light.

On recent designs, the transformer also supplies the low-voltage

power to the electronic control board.

Grid variations: Three various grid designs have been used in the history of these machines:

- Stainless frame with a four black plastic insulator strips, one across each of four sides.

See photo to identify.

Black molded-rubber electrical plug with two brass prongs.

This is the most common grid type on the electromechanical machines, and easiest to repair.

It interchanges with spring-clip type grid (difficult to repair) described next; the two grids are identical in shape and power connections,

and differ only in how the resistance wire is segmented and terminated.

Uses four long black plastic insulator strips, one on each side.

The resistance wire runs in serpentine fashion, bending around U-turns on the insulators, and terminating under screws

fastened into the ends of the insulator.

The upper cutting layer provides 10 parallel runs of resistance wire, and the lower layer 9 runs.

Shown in the 4th page of the Whirlpool original parts diagram.

Whirlpool supplied this grid as part numbers 326566, 2174861, WH2174861, 2174752, or 563887, all of which appear to be identical and interchangeable.

This grid was produced in the 1990s.

This grid is no longer produced or available as a new replacement part from any of the brands that used it.

- Stainless frame with U-shaped spring clips and small black plastic insulators on the end of each stretch of looped-end wire.

There are 10 wire segments on the upper cutting layer, and 9 segments on the lower, each segment with two looped ends, making for

a total of 38 electrical loop-contact points (!) and 4 sprung interconnect terminations, which makes for 42 points individually vulnerable to corrosion and failure.

Black molded-rubber electrical plug with two brass prongs (same as previous type).

See spring-clip grid photo to identify if you have this.

This type of grid is less commonly found today, being the oldest.

The spring-clip and wire segments are difficult to repair, there are

Uses numerous black plastic insulator pieces, one on each end of each wire segment, instead of insulator strips.

This grid can be replaced by the better insulator-strip design.

Whirlpool part numbers 758470 (3/4 inch square cubelets, the most common size) and 758469 (larger "standard" cubes, rarely used).

This grid was produced in the 1970s and 1980s.

Spring-clip grids are no longer produced or available as a new total-replacement part from any of the brands that used it.

Nor are the wire segments, clips, or connectors available (or to be recommended if they were).

If repairs to a spring-clip grid are necessary, the only practical method is to remove and discard all the spring-clip apparatus, keeping the original stainless frame on which

is added the new plastic insulator parts and standard resistance wire in the serpentine path.

- Stainless frame with a clear plastic insulator strip on each of two sides, white nylon electrical connector (see above) with two tinned receptacles (used in

newer Whirlpool, KitchenAid, SubZero, GE Monogram, and other models, easy to repair)

(photo when new,

photo of a well-used grid showing troublesome lime encrustation).

Sold as various part numbers including: Whirlpool 1173209, 2185614, 2217280, 2313601, 2313637, AP3859445, PS988982, and W10218012;

GE Monogram WR29X10016 and WR29X10073.

This grid was produced beginning in the 2000s and is still the current type sold in new machines today.

It is available as a new replacement part from parts distributors, which you may find by Web-searching for "Whirlpool" and the part numbers above.

The only design weakness of this generally perfected grid design is that the clear plastic insulators are pulled in tension from the stretched wire and

termination screw thread engagements, and these mechanical stress points are liable to fracture when the plastic gets old and brittle.

The polycarbonate plastic used is durable, but acid happens to embrittle polycarbonate. The manufacturer advises you to acid-clean

the machine frequently, but this has a long-term consequence of weakening the plastic insulators to where they become brittle and fail where

the wires or screws engage.

Despite the difference in design, these various grid designs use the same type and overall length of resistance wire,

and they all cut an 8 by 8 inch slab of ice into 110 individual cubes. Given that the machine is capable of producing about

2 or 3 slabs per hour, it can thus produce 5 to 8 thousand cubes per day. The bin holds about two days of production, which

makes for up to 16,000 cubes waiting to serve. That's a lot of cubes!

Removing the old, broken wire: To restring the wire, begin by removing the cutter grid assembly from

the ice machine by removing the two thumbscrews that hold the grid inside the bin, and disconnecting

the two-prong low-voltage power connector.

You can test the machine by keeping it running with the grid removed. Without the grid the machine should make ice in slabs that drop into the bin

and break. You can let the gridless machine run while you complete the grid repair.

Remove the plastic bezel from the grid by sliding it off while prying the notches up that hold it in place.

The resistance wire is strung in two directions, each a separate electrical circuit; these two are

wired in parallel by ordinary insulated tinned-copper wires to the 2-prong connector.

Likely only the upper level of the grid wire is broken, and you can restrict your repair to that one circuit, since

the upper wire breaks from the repeated impact of the ice slab coming off the evaporator; the lower level very

rarely breaks since it does not receive any such impacts.

The ends of the wire are clamped in place on top of eyelet connectors by stainless screws.

These screws have a Torx T20 head, so you'll need a Torx driver to loosen and tighten them,

(although if desperate you could grasp the screw heads with pliers).

Loosening these screws just a bit frees the wire ends. Unthread the old, broken wire from the back-and-forth pattern through

the plastic insulators at the edges. The insulators are captured on the metal frame only by the wire tension,

so the insulators will come loose from the metal frame when the wire is loose;

remember the orientation of the insulators for reassembly.

This is a good time to clean the grid with acid cleaner if it has lime encrustation or other debris.

Installing the new wire: Installing the new wire requires a skillful manipulation,

but the process is not too difficult with an educated technique that I will now explain.

Wrangling stiff wire is a romantic piece of smithy craftsmanship that has been largely forgotten in the modern

era. Rediscovering the forgotten secrets will reward you with the ability to economically repair the ice machine grid

whenever needed. My bit of reinvention was inspired by my observations of a curious genius in my college residence,

who practiced the art of restringing wooden squash racquets

as a lucrative gig business.

The tools required are: a Torx T20 screwdriver for the wire terminal screws, a bench vise, hardened wire cutters, and a pair of locking pliers (Vise Grips).

You will apply the locking pliers to the free end of the wire to provide a handle on the end of the wire. This handle allows you to stretch the wire tightly

down its path.

If you do not have locking pliers, you can improvise a handle on the wire by twisting the free end of the wire onto a screwdriver shaft.

You must first fix the grid frame in a secure work holder, such as a bench vise.

Rigidly fixturing the grid in a bench vise is necessary. Fixturing leaves both your hands free for the two-handed stretching task,

and lets you apply the continuous tension that properly stretches and strums the wire into the grid path.

If you don't have all of these tools available, you can improvise some of them with other tools you might have on hand.

Using ordinary electrical-wire cutters (meant for use with copper wire)

will cause a nick in the sharp edge of the cutter blades when you use them to cut the hard nickel-chromium resistance wire.

Use a hardened type of wire cutter if available, such as aviation snips, or else be prepared to suffer the nick to your

ordinary cutters.

A C-clamp and wood shims against a workbench surface can serve as a poor-man's bench vise to hold the grid assembly while

you work on it.

If you lack the Torx screwdriver, you can use ordinary pliers to carefully turn the head of the screw.

Little torque is required on these screws, since they are thread-forming types going into the plastic material

of the insulators.

Before installing the grid wire replacement, you should inspect the grid for other possible problems.

In some cases the grid may have broken or missing parts in addition to a broken resistance wire.

You can replace a missing Torx screw with a stainless #10 sheet metal screw cut to 3/8 inch length.

A failed or missing connector can be repaired with the replacement connectors I offer above.

Damaged or missing insulators will require the mail-in grid repair servicing (see above), because

the original manufacturer's parts have been discontinued and are no longer available otherwise.

The grid design is based on a serpentine wire which threads through black plastic insulators.

On rare specimens this plastic is found to be white, and on all the later

electronic models the insulators are invariably clear and open instead of threaded-through.

The assembly of the parts (stainless steel frame, plastic insulators, and taut wire) is held together

by the wire tension itself.

Check the length (before it was broken) of the removed wire; typically this is 8 feet 3 inches. Unspool

a slightly longer piece of new wire (I use 9 feet), taking care not to sharply bend the wire while you

gently free the loose coil supply from its inevitably springy tangle. If you bought your new wire from me, then you should have received one

20 foot length, which you can conveniently just cut in half. Fold this 9 or 10 foot cut of wire itself in half to find its approximate center.

Don't actually sharply bend the center, but instead form a half loop there around your finger.

Thread the ends through the middle hump of the insulator which is opposite the insulator that holds the connector screws.

Thread these two loose ends respectively through the rest of the serpentine pattern, until you reach the

end by the connector screws (not unlike lacing a shoe in an uncrossed pattern).

You should have at least several inches of extra wire past the connecting screw on both ends; if not, shift the wire

to even the ends.

Once the loose wire is threaded into place, begin the technique of fastening it in place under tension.

First, take one loose end of the wire and wrap it clockwise taut around the connector screw

by one-half or three-quarters of a turn, with the eyelet connector above it, and tighten down the screw with the Torx driver.

Next, using your fingers, starting at the same screwed-down end, stretch the wire taut across the grid opening in one direction,

and again reversing to the next direction, hand-over-hand, until you reach the other end, and have taken up all the

slack you can. It is not necessary at this stage to have the wire very tight; just enough to keep the wire from sagging and to straighten

any kinks is enough. Use your fingers for this; do not use pliers or other tools which might nick or otherwise damage the wire as you manipulate.

Now here is the secret technique to getting a tight wire all across the grid: wrap the loose end around

its still-loose connection screw one-quarter turn, and maintain constant tension on the loose end while you repeatedly

"pluck" the spans of wire from the far end back to the loose (tensioned) end.

By "plucking" I mean that you pull on the second span from the fastened end to tighten the first span,

then take up the slack of the second span by pulling on the third, then the third from the fourth, and

so on, until the slack is pulled out of the grid on the the loose end by the constant tension.

This constant tension could also be provided by another person helping you with a pair of Vise-grip pliers on the end of the wire,

or a weight of a few pounds likewise attached, but you must have both your hands free to "pluck".

Repeat the "plucking" a few times until the strings are "moderately" tight, "moderate" as in playing a low

note when you pluck them like a guitar string, not so tight as to distort the grid frame out of its rectangular form.

After this step you can "strum" the from the fastened end to the loose end to tighten the

segments further, strumming with one hand while maintaining continuous tension on the loose wire end

with your other hand. "Continuous" means that you cannot allow the tension to slack off even for a moment, until you

have the second free end wrapped around and under its fastening screw head, and have finally tightened the screw to lock

the wire under tension.

Before the final tensioning, when you have the wire in place over its circuitous length,

carefully inspect each of the wire bends across the plastic insulators

to verify that the wire is properly routed across the radius bends provided on the insulators.

Confirm that no part of the wire is misplaced on the insulators.

Also check that the plastic insulators are captured into their proper seatings in the metal grid frame.

You must now coordinate several finishing motions skillfully at once: (1) tensioning the wire with the pliers as handle,

(2) strumming the wire to remove all slack and distribute the tension evenly along the serpentine path,

(3) wrapping the wire around the screw, and (4) tightening the screw to lock the wire in place under tension.

You must maintain constant tension on the free end of the wire while plucking the tension throughout

the wire circuit, until you have completed stretching the free end around the terminal screw and locked the tension by

tightening the screw. If you allow the wire to go slack before locking it down, you must reverse this finishing step and

repeat. These finishing steps are like a simple musical recital performance, which succeeds only when every note is correctly played

in the correct order. At least your piano teacher is not there to scold you for bungling it. Beware the yips.

The goal is only to have the wire tight enough to not sag.

Once you have pulled all the slack out and strummed the wire segments all tight,

fasten the loose end by wrapping the wire clockwise around the second connector screw like

the first and tightening the screw, all the while maintaining the tension until the second screw is set and the wire is locked down into its

final tensioned state. Trim the excess wire on the screws where the wire is wrapped around the screw, being

careful not to nick or damage the installed portion.

The taut wire might still have very slight kinks remaining on the spans across the grid frame.

These minor kinks will not interfere with the proper cutting action of the grid.

You can straighten the kinks by stroking against them with the side of a wood dowel or pencil.

Don't pinch the wire spans with metal pliers to straighten kinks;

this will mar the wire and create a weak point where a future break could occur.

Testing and reinstalling the rewired grid: Reassemble the plastic bezel to the unit, and test the grid

by connecting it to the ice machine before you install it in place.

To test, place the palm of your dry hand against the grid wires when the ice machine is running and the

grid is connected;

the wires should feel slightly but distinctly warm when no ice slab is on the grid.

Once tested, you can reinstall the grid into the machine.

At the next harvest, observe that the grid takes about 10 minutes to cut a slab of ice into cubes.

|

Send your plastic-insulator grid in for repair: If you want me to repair your faulty plastic-insulator grid for you, you can ship me your broken

unit and include a check for $135, or order online with credit card.

See the packing instructions, shipping address, and online ordering here, or use the

buttons at the right.

Return shipping is included; USA addresses only.

Turnaround on this repair is 1 week after we receive your broken unit.

Remember that you can still make uncut ice slabs while you're awaiting the repair;

see ''cutter grid is actually optional'' below.

|

Click here to buy the plastic-insulator grid repair service now.

|

|

Send your spring-clip grid in for repair: If you have a faulty spring-clip grid, you can ship me your broken

unit and include a check for $190, or order online with credit card.

See the packing instructions, shipping address, and online ordering here, or use the

buttons at the right.

Return shipping is included; USA addresses only.

We remove all the trouble-prone spring-clip parts and replace them with plastic insulators and all-new wire.

Turnaround on this repair is 1 week after we receive your broken unit.

Remember that you can still make uncut ice slabs while you're awaiting the repair;

see ''cutter grid is actually optional'' below.

|

Click here to buy the spring-clip grid upgrade and repair service now.

|

Complete grid assembly: If you want to buy a complete cutter grid assembly,

check my ordering page for availability and price of units I have refurbished.

You can also order a grid with the plastic panel at additional cost (normally you'll just switch

the old panel onto the new grid, but sometimes the grid and panel have gone missing).

|

Repairing or upgrading the old spring-clip type cutter grid variation:

A much older design for the cutter grid was used up to about 1995, and differs from the more recent designs described above.

The older style uses short segments of resistance wire held in place (and electrically connected) by individual stainless U-shaped spring clips and posts,

which pressed against small plastic insulators. This was a nightmare design, involving 128 small parts, all interlocking and held in place by spring forces.

Instead of two lengths of wire, there were 19 segments, chained through 38 spring-loaded electrical point contacts.

Each segment consists of a short length of wire terminating in eyelet loops of about 3/32 inch diameter, the length being

about 9 inches from eyelet center to center. For some unknown reason, the top and bottom grid layers use slightly different segment lengths.

When any of the 38 electrical contact points is slightly disturbed (such as by a lime deposit forming to inhibit the electrical contact),

the resulting increased resistance creates a hot spot, which tends to further degrade the contact. Once this process starts, the localized heat tends to

soften the small plastic insulator. Then the spring force squishes and remolds the plastic, causing the spring force to relax and the contact to worsen,

reinforcing the problem.

Sooner or later every spring-clip grid develops this spiral into poor performance and gradual failure.

Even if the problem is simply a broken wire, repair is difficult, because the spring clips make assembly a four-handed job requiring special tools.

Restringing a medieval harpsichord is an easier task.

Even if you do skillfully identify the failed segment and successfully repair it,

it is likely that another segment will soon fail likewise, making repairs futile in the long run.

The wire segments have long been discontinued from Whirlpool; instead we use a custom winding jig to fabricate them from stock resistance wire,

or supply salvaged Whirlpool parts from grids that we have upgraded.

I don't recommend the repair attempt versus getting rid of the clips with an upgrade,

but I do offer a kit of 3 of these segments for $26 if you want to heroically repair a spring-clip grid yourself (formerly known as Whirlpool part number 588109).

While spring-clip grids do have a limited service life, renewal is available.

Instead of repairing them, what I recommend is upgrading the old spring-clip grids to the improved all-insulator format.

This provides a reliable and restringable grid that should last longer than the rest of the machine.

Happily, Whirlpool used the identical stainless steel frame in the spring-clip grid as the improved all-insulator type.

This allowed spring-clip grids to be torn down to the frame and rebuilt with the newer all-insulator parts.

After Whirlpool discontinued the four plastic parts specially required for the upgrade (about 2010), for some years there was no feasible rebuild, the only

option was to buying a rather high-priced new grid.

But then these grids themselves were also discontinued; soon they became scarce, costly and eventually unobtainable.

For some years before 2018 many machines, still running well otherwise, became unusable due only to a failed grid.

Since 2018 I have been custom-fabricating an improved plastic insulator kit to upgrade spring-clip grids to a readily repairable and rugged design.

I make these parts from sturdy Delrin in my CNC machine shop.

This kit replaces the insulators that have been unobtainable since Whirlpool discontinued them some years ago.

If you have a spring-clip grid in need of repair, please use the button in the previous section (for sending in a grid to rewire)

to send it to me for this custom rebuild and rewire.

If you just want to order the insulator kit and wire to rebuild a spring-clip grid yourself,

please make the same send-in-for-rewire order, and email me a separate note indicating your request to send the parts kit only.

You'll basically strip down the old grid to the bare stainless steel frame, and reassemble it with new wire and insulators, reusing the old

plug (or optionally upgrading the plug, too). The result will perform reliably and be conveniently maintainable.

I've also been able to upgrade rare old grids from manufacturers like Marvel, which used the Whirlpool spring-clips in various geometries

that differ from the Whirlpool standard. These grid types were also used, and still are used, in many larger commercial machines still in service.

The CNC fabrication of these parts allows us to readily make them to fit different grid spacings and sizes. If you have a valuable old machine

that needs a grid upgrade, email me snapshots of what you're facing, so I can respond with whether it is feasible within this design, and

I can quote what it would cost.

|

Click here to buy older-type wire segments now.

|

Transformer for Cutter Grid in Electromechanical Machines:

The only low-voltage circuit in the older electromechanical machines was for the ice cutting grid (and the lamp inside if equipped with that feature).

The compressor and controls operated on 120 VAC, and would continue to operate despite a failure of the low-voltage transformer.

If the transformer were to fail, the machine would still make ice slabs and harvest them properly, but the grid would not heat.

Ice slabs would then pile up on the grid, since they were not being cut and falling through into the bin.

A proper diagnosis of such a situation must test for a failure of the grid itself, versus the connections, versus the transformer failing.

If the transformer (or a connection to it) has failed, applying a multimeter for voltage to the grid power receptacle will show no low-voltage power

when the grid is removed, while about 9 VAC would be expected.

Removing the grid and measuring the resistance across the plug prongs with a multimeter should read about 4 or 5 ohms.

One cause of transformer failure is

an inadvertent short-circuit in the grid circuit (such as from a broken grid wire touching the grid frame); this typically causes the transformer to overheat and fail.

Sometimes transformers just fail inexplicably.

The original transformer part for the older electromechanical machines is no longer made and doesn't seem to be available from Whirlpool.

A stock generic unit made by Hammond, their part number 166L8 (8.5 VAC center tapped, 2 amps), which is sold by digikey.com as part number HM510-ND, is a suitable substitution.

You can order the

HM510-ND online from digikey.com

for about $22 plus $10 shipping (in 2018 pricing).

You'll also need two each of 3/16-inch and 1/4-inch male disconnects (digikey.com

94807-01

and

94811-01

respectively) to fit the original connectors on the machine, or you can just splice in directly.

The 1/4-inch size disconnect is a widely used standard, but the 3/16-inch size disconnect is unlikely to be found in hardware stores.

The Hammond part provides five lead wires: two are black (primary) and connect to the 120 VAC line; two are solid green (secondary) and connect to the grid connector.

The fifth wire, which is green with a yellow tracer, is a center tap which is not used or connected in this application; instead you should fold it over, cover with

heat-shrink tubing to prevent inadvertent contact, and use cable ties to tuck it away.

If you diagnose a failed transformer in the newer electronic machines, these parts should still be obtainable and you should use original replacements.

The transformer for newer electronic machines powers not just the grid, but also is the input to the DC power supply for the electronic PC board controls and interior lamp(s).

Some versions have two separate transformers for these two circuits.

Grid lifetime:

How long should a grid last? Not as long as you might think.

These things break because a heavy slab of ice drops on to the top grid layer every time the unit goes through

a harvest cycle.

Over the years, my grid seems to have lasted a typical 50,000 cycles before it breaks.

Considering that a unit could run 50 cycles per day, that could be less than 3 years.

(But that's also 25 tons of ice, roughly a semi truckload.)

Your grid will of course last longer if your machine runs only intermittently, but while the

machine itself may last for decades, the grid won't without an occasional minor restringing repair.

The grid wire we supply above is slightly heavier than the original, and consequently tends to last much longer.

Repairing the Harvest Thermostat Solder Attachment

The older design of this machine used electromechanical controls, including a harvest

thermostat on the evaporator plate that clicks on and off with the ice slab temperature. If your machine uses the newer

electronic controls, you will have an electronic thermistor on the evaporator instead of electromechanical thermostat,

and this section does not apply.

The evaporator plate in the top area of the ice machine circulates the hermetically sealed refrigerant

(R-134a lately, or R-12 in very old machines), which boils off to carry away heat from the waterfall passing over the plate, resulting

in a layer of ice being progressively built up. The top of the evaporator plate, where the ice forms, is smooth.

The bottom is a complex affair containing the refrigerant line connections, and a bracket and clamp holding a capillary tube

from the harvest thermostat. A complete assembly (327505 evaporator $266.02) is the only

replacement part available from Whirlpool, but the old part can likely be repaired.

To diagnose the problem, it helps to understand the principles on which the machine makes ice.

The running machine is always in one of two modes, either ice-making (chilling the plate) or harvesting (warming the plate).

The capillary tube senses the temperature of the evaporator plate, which

triggers two control events in the machine, depending on what the state of the machine is, and on

the temperature reaching a level well-below or well-above freezing:

- In the ice-making state,

when the evaporator plate temperature drops below a sub-freezing setpoint (set by the front-panel

ice-thickness control), the unit switches to the harvesting state, reversing the refrigeration and thus

heating the plate so that the ice slab thaws slightly and slides off onto the cutter.

During harvesting, the water valve opens to refill the recirculating reservoir and flush the

"used" water out via an overflow drain, while the recirculation pump stops.

(The freezing process removes minerals from the water in the deposited ice, and

concentrates them in the "used" reservoir water, necessitating a flush lest the minerals concentrate

in the reservoir.)

- In the harvesting state,

when the evaporator plate temperature rises above an above-freezing setpoint (the ice slab has

slid off the plate, and the reversed refrigeration continues to heat the plate),

the harvest state is ended and the unit switches to ice-making again. The water fill valve

closes, the recirculation pump starts, and the refrigeration unit switches back to chilling

the plate.

The bracket and clamp holding the capillary tube are about 1" wide by

4" long.

The bracket itself is soldered to the bottom front of the evaporator plate,

and a smaller clamping plate is held by a screw post and nut to the bracket.

This creates a solid thermal connection between the capillary tube and the

bottom of the evaporator plate; inside the tube, a liquid expands and contracts

with the sensed temperature. The tube transmits this expansion/contraction pressure

to the thickness control thermostat at the front panel,

where the pressure triggers the switch that controls the cut-out

and cut-in of chilling versus harvesting.

A few inches of the capillary tube should also be soldered to the bottom front lip of the evaporator plate.

This helps it to quickly sense the rising temperature during the harvest cycle, which

should end as soon as the ice slides off.

The failure of the bracket solder joint occurs because of the repeated cycling of sub-freezing

chilling to make ice versus above-freezing thawing to harvest the ice.

The area is always wet, and the solder joint will typically have small pockets

or bubbles, which when wet will freeze and become slightly larger due to the expansion

of the ice. Each freeze-thaw cycle enlarges the flaw slightly, and eventually this

grows into a large fracture, just like fracturing of mountain stone from years of

winter/summer cycles.

If you suspect you have the problem of the fractured solder joint,

you can inspect the joint by removing the cutter grid and reservoir bucket.

You can recognize the bracket, since it is the only item in the vicinity having

a screw post and nut.

If the solder joint does not appear intact along the entire length, but appears

cracked or slightly separated, then you have this problem, but perhaps

not very badly (yet). If the joint is mostly cracked, such that you can

wiggle the bracket; or if the bracket is completely loose from the plate

and is being held only by the capillary tube, then you have a definite

problem needing repair.

The bracket is hard to view directly without

pulling out the evaporator plate, which is a big job. You should be

able to blindly feel around to the front or back of the bracket, nudge it

with your fingers, and find it moving relative to the evaporator plate.

Indeed, if the solder joints have almost completely failed, the bracket

can fall right off with this manipulation.

While I used to recommend a difficult repair of resoldering the bracket,

you may want to consider the re-location bracket

kit that Whirlpool introduced in 2006 to deal with this problem.

The repair to resolder this bracket is a bit challenging. You must

first remove the cutter grid (remove two thumbscrews), reservoir bucket

(remove two thumbscrews), and recirculation pump (remove three acorn nuts

at rear wall, disconnect recirculation tube from top of evaporator plate).

Your design may vary slightly, but so far these steps should not be

too difficult.

The first difficult step is next, to get the evaporator plate out of the

interior of the bin while it is still connected to the refrigeration

system. Remove the two thumbscrews that hold the plate in place.

Observe that the plate is free of fasteners but held in place by 1/4"

refrigerant tubes and 1/16" capillary tubes, made of copper, perhaps

tinned, somewhat flexible. You must now manipulate the plate out of

the bin, bending the refrigerant tubes to allow the plate to swing out

through the door, such that it presents the bottom of the plate in the

upwards direction. While the copper tubes cannot take a lot of this

kind of bending, and you should be careful not to kink them, they can

take a few rounds of this type of manipulation before they

work-harden enough to crack.

If you should crack the refrigerant line tubing, you will hear a hissing

sound from the pressurized refrigerant gas escaping, possibly with some

entrained oil. If the refrigerant escapes as a cold liquid spray, stay

clear of it (evaporating R-134a can cause frostbite in contact with skin).

If the leak is not too close to the plastic bin, it might be possible to

repair it with a soldered patch or repair fitting, but that will require

an evacuation and recharge of the refrigeration system which is beyond

the scope of this document. Otherwise you will need a replacement

for the evaporator plate unit which may cost more than the value of the

repaired system.

Assuming you have the bottom of the plate facing up, and clear of the bin,

and haven't cracked a tube, you can better inspect the condition of the

thermostat capillary tube bracket and the solder joint. If it indeed

shows fatigue or failure, you should repair the joint. Good soldering

practice is essential here. Clean the area as best you can first with

a wire brush, and apply a generous amount of non-acid flux. Heat it up

quickly (a pencil torch is marginally effective; I use a Turbo-Torch to

get a lot of heat), and feed and wipe with lead-free solder. Apply and

withdraw the flame in cycles to keep the area just above the solder

free-flow temperature, and keep the overall time to the minimum needed

to get a good joint. Don't worry about solder splashes or blobs falling

across the plate; they'll clean up eventually even if they wind up in

the reservoir later.

Soldering or brazing on a charged refrigerant system is normally not feasible.

The liquid refrigerant and oil should have collected in the bottom of the unit and not

up in the evaporator plate, so that the soldering of the adjacent surface

to the refrigerant circuit does not require evacuation of the unit.

You are not loosening a soldered joint or fitting under pressure, just the

mechanical attachment of a bracket. If you can

get it done quickly and at a low temperature, you can expect that the

heat damage to the residual oil or refrigerant in the area will

not be enough to impair the function of the refrigeration unit.

The ideal technique would be to add a repair fitting to the process

tube on the compressor, evacuate the refrigerant, flush the oil, charge

with inert gas, solder, evacuate, and recharge the refrigerant system,

but this may not be practical.

Once you have a good solder repair, and the part has cooled, you can

reverse the disassembly, starting with manipulating the evaporator plate

back in to position at the top rear of the bin. Replace the circulation

pump and hose, the reservoir bucket, and the cutter grid. Before replacing

the bucket and grid, you may want to start the unit and feel the evaporator

plate with your hand to see if you still have refrigeration operational.

A new solder joint should last some years at least. Recurrence of this

problem does seem inevitable, because of the nature of the freeze-thaw

cycling and how it repeatedly applies destructive force at any wet gap

or void in the joint.

You will find stray bits of solder and related debris in the reservoir

or ice bin after performing this repair and running the unit. Of course

you will have used lead-free solder, so this is not a concern.

You may be told by a repair service that this is a brazed joint that is

impossible to repair.

Refrigeration technicians like to braze joints because this is much

stronger than soldering, and part of their technical training and equippage.

After inspecting 8 of these units, and

repairing one, it is clear that this joint is made at the factory with

ordinary low-temperature soft solder that is quite feasible to fully repair.

The hard part is getting the assembly out of the ice bin without cracking the

connected tubing.

Someone emailed me to report that he had repaired the bracket attachment

with epoxy cement instead of soldering, which can be done inside the bin

without the difficulty of extracting the evaporator assembly.

While the thermal junction cannot be quite as good through epoxy versus

solder, it apparently is enough to work, perhaps with a bit of temperature

offset to the thickness control. Stainless steel bonds well with epoxy,

but make sure the metal is cleaned, warm and dry before trying this.

Adjusting the Harvest Thermostat

If your ice thickness control doesn't respond properly, but your sensing

bracket seems to be properly in place, it is possible the thickness

control thermostat itself has simply drifted out of calibration and just

needs an adjustment. This is an easy repair, assuming you ruled out the

loose bracket first. Remove the escutcheon plate from the front, exposing

some tiny adjustment screws on the thickness control for the cut-in

and cut-out temperature setpoints. You can twiddle those adjustments.

The cut-out screw sets the colder temp for the harvest trigger, the

cut-in screw sets the warmer temp to end the harvest. Set the control

(knob) to the middle of the thickness range, and wait for the ice to

build to a medium thickness, and then adjust the cut-out screw until

it triggers the harvest. These screws have a range of several turns

of adjustment, so you may have to turn them 1/2 or a full turn before

you see any difference in performance. When making these adjustments,

count the turns you apply to either screw, making notes of that, so you

can return the control to its prior settings if you get lost.

Even if the bigger problem is the loose evaporator bracket, you can

compensate to an extent by adjusting to cut-out setpoint on the thickness

control to a warmer temperature. But you won't have fixed the problem

in the long run, and the thickness control will be poorly responsive

since the thermostat doesn't have a solid thermal contact with the

evaporator plate. Poor response can result in harvest intervals that

start too soon, too early, or inconsistently; and also in harvest times

that are too short or too long.

If you want to adjust the harvest thermostat to shorten the harvest

time, remember that the harvest time is deliberately longer than the

time needed to just refill the reservoir. The reservoir is flushed with

an excess of refill water, which then overflows into the drain tube,

so that the high mineral content of the old water is replaced with

new water.

Repairing the Solenoid Valve

As described above, the solenoid valve that controls incoming water flow

can fail in an open or closed manner. This is Whirlpool part number

386433 on my unit. This valve is located at the bottom right front of

the unit, just inside the kick panel, where the water connection is made.

These valves are a common replacement item, and in fact easy to remove

and replace if you just want to pony up for a new one. This same valve

is apparently used on a lot of appliances, as I have seen it on washing

machines and dishwashers, so if you don't want to fuss with the rebuild,

you can take it to an appliance parts counter and expect to find it for,

oh, $40.00, which is most likely about $39.99 more than it will cost to

fix it yourself. (I'll admit than now when I see someone discarding a

dishwasher or refrigerator on the curb on trash night, I'm tempted to

stop and look for a solenoid valve to scrounge!)

The 1-cent failure is nothing more than the inevitable deterioration of a tiny

rubber gasket which is trivial to repair. You might fix this faster

than you could even find a replacement.

To remove and repair the valve, first remove power (120 VAC power

runs this solenoid). Shut off the water supply, and disconnect the

water inlet and outlet connections to the solenoid valve. Remove the

electrical connector. Remove the mounting bracket screw(s), freeing the

valve. Remove the screws to disassemble the valve unit, observing the

solenoid plunger with a recess tip containing a tiny rubber gasket plug

(or remnants thereof). This rubber item is originally a disc about 1/8"

diameter and 1/16" thick, stuffed into a recess of the same size on the

tip of the plunger cylinder. The rubber may be partly disintegrated or

missing altogether.

You can cut your own replacement rubber piece quite easily. I made mine

using a leather punch on a 1/16" thick sheet of rubber gasket material.

The usual Buna-N (nitrile rubber) material is fine, such as is available

from plumbing suppliers, auto parts stores, or online at Enco (such as p/n 240-2326).

You could also take a common

faucet washer, and carve it with a razor-sharp hobby knife to proper thickness and

diameter.

The exact disk shape is not critical; what is critical is that the outside face

is flat and smooth, which you can ensure by just using an original flat surface of

the faucet washer on that side. Reassemble, reinstall, enjoy the satisfaction of

a cleverly improvised, do-it-yourself success.

Some of the service manuals refer to 0.31 gallons per minute flow from the

solenoid valve. This would be a good target flow to measure when testing the function of the

valve with the plumbing disassembled and the water running into a bucket.

Run the valve open for a timed minute while catching the water in a bucket, and measure the water volume caught.

It should be 0.31 gallons (40 ounces) or more.

Testing for a stuck-closed solenoid valve:

Testing the solenoid valve for being stuck-closed is not difficult.

Understand first that this valve only opens during the harvest portion of the cycle,

when the fan has stopped and the refrigeration unit is reversed and hissing slightly.

If the machine has been turned off and sitting idle for a while, turning it on should

not activate the water valve solenoid, it should simply start chilling,

and if there is water in the reservoir, it will proceed to make a slab

of ice; if the reservoir is empty, the evaporator plate will chill down

rapidly, and in a few minutes the harvest cycle will trigger, only then

should the water solenoid valve open. If you've removed the reservoir bucket,

then you should be able to see the stream of water entering the unit, and even

catch it in a bowl to measure the volume.

The hot gas solenoid and water valve solenoid are in parallel, so if

the unit reverses during the harvest and rapidly warms the evaporator plate,

then the controls are OK.

The switching of the solenoid valves is performed by the thickness control

thermostat behind the escutcheon plate.

Testing for a stuck-open solenoid valve:

To test if the solenoid valve is stuck open, even just a trickle,

you can remove the reservoir bucket and see if water runs from the

supply tube during the chilling part of the cycle. If you suspect a

trickling valve is spoiling performance, you can shut off or disconnect

your water supply completely (make sure you have a solid shutoff valve,

not even allowing a trickle) at the end of the harvest, and see if the

performance problem goes away for the rest of that cycle.

Testing for restricted water flow:

To measure how much make-up water your machine is admitting each cycle,

remove the reservoir bin and catch the water flowing in during the harvest.

This volume should be at least several changes of the reservoir volume of

about 1/2 gallon (the slab itself will have consumed about 18 ounces of water),

so you should catch about a gallon or more during a 1- or 2-minute harvest.

If the supply pressure is OK, but the machine admits less water,

then you must have some kind of restriction or too-short harvest time.

One can also benchtop-test the solenoid valve for stuck-open, stuck-closed, or restrictions,

by removing it entirely and activating it manually.

The water inlet connects to an ordinary garden hose.

For the electrical test, I assembled a "cheater" AC plug and cord with 1-amp inline fuse and

female spade lugs, and connected this to the solenoid's terminals to apply 120 VAC.

Apply the inlet water pressure, and (keeping yourself dry) briefly insert the

AC plug into an outlet.

Recharging the Refrigeration Unit

This section is for technicians and advanced do-it-yourselfers who have the tools and knowledge

to charge A/C and refrigeration systems.

If you're not a do-it-yourselfer and wanting advice about hiring a technician offering an expensive repair,

see my tips under diagnosing poor performance below.

The performance specifications on the "Service and Wiring Sheet" indicate that the

machine should harvest a medium-thick (about 0.45") slab of ice every 18 to 22 minutes under favorable conditions

(ambient temperature 70 deg F and incoming water temp 60 deg F).

This production rate will slow to 30 to 38 minutes under unfavorable conditions

(ambient temperature 100 deg F and incoming water temp 80 deg F).

If the production is slower, then the cause may be an undercharged refrigeration system.

The refrigeration performance of the ice machine design is very sensitive to undercharging,

because (1) the refrigerant charge is so small to start with, only a few ounces,

hence a tiny leak can turn into a problem quickly, and

(2) expansion is controlled by a capillary-tube (no feedback,

"open loop" control) instead of an expansion valve (closed-loop feedback control).

While this open-loop sensitivity is a disadvantage in that any leak will degrade performance,

it also makes the diagnosis of a low-refrigerant condition easier because the degradation

is easy to observe and detect.

Another symptom of low charge is that the slabs of ice are

distinctly thinner in the middle (not just wavy).

The refrigerant circulates through the evaporator plate in a rectangular spiral from

the outside edge to the center. If the refrigerant is slightly low, it boils off and chills

the edges well, but by the time it reaches around to the center, it is all evaporated, and there

is no phase change remaining available in the refrigerant flow to chill the center area.

See my tips under diagnosing poor performance below.

Recharging the system first requires that you add an access fitting,

because the system as shipped from the factory is a sealed unit.

A 1/4" OD copper process tube exits the front of the compressor, which at the factory

was used to charge the system, pinched off, and brazed shut.

This is the suction side of the compressor.

This process tube is intended to be fitted with an access fitting should

recharging ever be needed. I used a 1/4" flare male Schrader valve fitting, which

happens to fit my refrigeration gauges. An automotive low-side fitting is more appropriate.

While soldering or brazing a fitting on the process tube is the most reliable

way to proceed, installing a clamp-on

line-piercing valve [grainger.com example]

is feasible and much easier.

This has the advantage of requiring

no soldering or brazing, instead using mechanically compressed elastomeric seals,

but will eventually leak when the seals get old.

This line-piercing valve will provide a 1/4" flare fitting, to which you can add an

adapter for 1/4" flare to R-134a low-side quick-connect fitting. This adapter is

available for a few dollars in the auto parts at Walmart (sold for retrofitting

R-12 auto air conditioners). Then you can use normal R-134a recharging cans and gages

from Walmart to add refrigerant, although you must take care not to overcharge since the

system contains less than 1 lb of refrigerant total.

To add this fitting, I followed these steps:

- File a slight cut in the process tube,

with a small triangular file or piece of hacksaw blade, to vent the existing refrigerant.

A slight cut will allow the refrigerant to escape slowly as a gas, leaving the oil

behind in the compressor. A faster outflow would vent some oil out as a mist, entrained in

liquid refrigerant.

It is normal for a little oil to escape at first, which was already in the process tube stub.

-

Cut the tube off, inside of the crimp, using a tubing cutter to get a clean, square cut.

-

Clean the oxide off the outside of the cut tubing end and the mating surface of the access fitting to prepare

them for for brazing or soldering.

Apply a small amount of soldering flux to these surfaces if that is your practice.

Use a Q-tip and solvent to wipe the oil off the inside of the tube.

The tube should be pointing in some generally upward direction so more oil won't run into it.

-

Remove the valve stem from the Schrader valve on the access fitting. This protects the rubber components in the stem

from the high temperatures of soldering. You also don't want to seal the system during the

soldering process, as this will tend to build up pressure that will blow the fitting off the end of the tube

before the solder freezes.

-

Braze or solder the access fitting onto the tube.

I used soft 50/50 lead/tin solder, since the temperature is much lower than brazing and

the action is quick, minimizing the oxidation of the inside of the tubing.

The lead is of no consequence in the refrigeration circuit, since it does not contact the

potable water or ice.

Brazing will yield a much stronger joint, at the risk of oxidizing the inside of the tubing

and contaminating the system. The solder joint has proven

adequate on this small tubing and minimizes the contamination from heat oxidation.